Bioreactor

HPB Mini Parallel bioreactor

Basic information

● Model: HPB Mini series

● Vessels volume: 200mL, 500mL, 1000mL, Support customization

● Support for expansion: 2 groups per unit, up to 64 groups can be expanded

● Control system: HPB-Control V2.0

● Can be used for laboratory bacterial fermentation, cell culture and enzymatic biochemical reactions

Description

Specification

Optional items

|

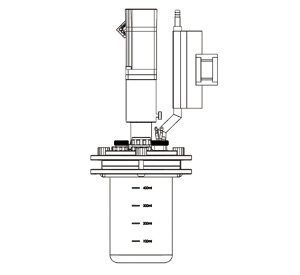

The best vessel system in the industry

● Adopt APPLIKON homology design concept, apply the most mature solution

● The pore adopts a modular quick-release design to reduce dead corner, to prevent contamination ● Exhaust gas condensation adopts anhydrous temperature control scheme ● The temperature of the vessel can be controlled by cooling water (circle bottom) and anhydrous temperature control (flat bottom) |

|

|

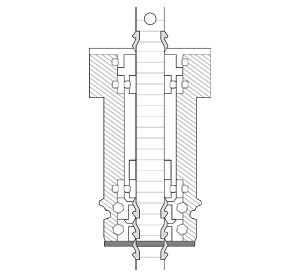

H-Mix® advanced mixing system

● Innovative no-seal design, industry first, patent protection

● No mechanical seal pollution and dead corner, the stirring system is cleaner and more hygienic ● Compared with the traditional machine seal stirring, the operation noise and shaking is small, the operation is more stable ● No installation guidance, no installation maintenance, use as input |

|

|

Excellent HPB-M controller design

● Construction of the latest Siemens hardware platform for SIMATIC S7-1200

● Local high-definition large-screen HMI+WinCC dual control design (WinCC optional) ● Bus control technology, parallel operation, precisely control ● Support software data analysis, comprehensive data information management and design of experiments (DoE) ● Built-in HPB-Control control software, which can monitor and control up to 8 groups of 16 vessels in total |

|

|

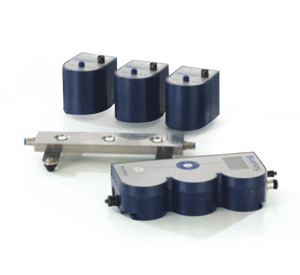

Building block modular BBM construction design

● Benefit by the application of the new bus technology, the product can realize the building block modular BBM construction design

● The main controller can control all the BBM modules built, no need to replace the controller and hardware ● Flexibility for laboratory-scale aerobic, anaerobic bacterial, yeast and fungal bioprocessing ● Specialized BBM modules such as gas mixing station are designed for cell process ● At present, BBM modules can be realized: building block modules such as feed pump module, automatic air intake module, exhaust gas module, etc., which will be continuously improved and adjusted in the future. |